measuring thickness of fiberglass using ultrasonic|ultrasonic gauge diagram : OEM In thickness gaging applications, ultrasonic techniques permit quick and reliable measurement of thickness without requiring access to both sides of a part. Calibrated accuracies as high as ±2 micrometers or ±0.0001 inch are . The latest tweets from @sarahcaus

{plog:ftitle_list}

Vantagens de ser um cliente Ingresso.com. Salvar Cartões. .

Ultrasonic Equipment Used for Fiberglass Thickness Measurements. Fiberglass measurements are normally performed with precision thickness gauges, such as the 39DL PLUS™ gauge or .In thickness gaging applications, ultrasonic techniques permit quick and reliable measurement of thickness without requiring access to both sides of a part. Calibrated accuracies as high as ±2 micrometers or ±0.0001 inch are . We’ll show you how to set up your 38DL PLUS™ thickness gauge with an M2008 transducer to measure thick fiberglass composites. Learn more at Olympus-IMS.com.S.All common plastics, fiberglass, and composites can be measured ultrasonically, with access to only one side of a material required. Precision ultrasonic thickness gauges can help .

A specific thickness gauge model which is suitable for measuring materials such as fiberglass is the Fiberglass Ultrasonic Thickness Gauge. Fiberglass is widely used in the boat manufacturing industry for recreational . Ultrasonic thickness gages can be configured for glass, plastics, metals, ceramics, fiberglass, and composites. It is possible to do in-process or on-line measurement of rolled metal and extruded plastics, as is measurement of .The Ultrasonic Thickness Gauge can measure a wide range of materials including metals, plastics, ceramics, glass, and other ultrasonic conductive materials down to 0.01mm. It is equipped with a large, easy-to-read, backlit .

The 45MG is an advanced ultrasonic thickness gage packed with standard measurement features and software options. This unique instrument is compatible with the complete range of Olympus dual element and single .Fiberglass pipes and tanks: These products can be measured both in manufacturing and following installation to verify wall thickness and detect delaminations. Fiberglass boats: Boat manufacturers and marine surveyors can measure hull thickness using high-penetration gauges if necessary for larger boats. Gelcoat thickness can also be measured .A PosiTector 6000 probe is generally recommended over a PosiTector 200 probe for measuring coating thickness on metal substrates because – Lower cost; Larger selection of probes (none requiring the use of an ultrasonic couplant gel) Greater accuracy; Unlike PosiTector 200 probes, adjustment is not required for most protective coating properties

ultrasonic thickness theory

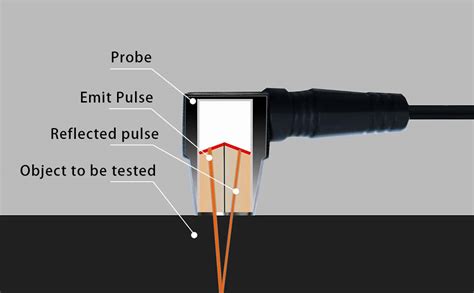

An ultrasonic thickness gauge is a measuring instrument for the non-destructive investigation of a material's thickness using ultrasonic waves. The usage of an ultrasonic thickness gauge for non-destructive testing to check material properties such as thickness measurement, is regular in all areas of industrial measurements. U ltrasonic thickness gauging is a widely used nondestructive test technique for measuring the thickness of a material from one side. It's fast, reliable, and versatile, and unlike a micrometer or a caliper it requires access to only one side of the test piece. The first commercial ultrasonic gauges, using principles derived from sonar, were introduced in the late 1940s.Ultrasonic thickness gauging is a widely used nondestructive technique for measuring the thickness of a material from one side. Just about anything made out of metal, plastic, composite, ceramic, glass, fiberglass, or rubber can be measured. This tutorial provides a basic introduction to the theory and practice of ultrasonic thickness gauging .

The use of fiberglass represents an extreme challenge for the evaluation of casing integrity as well as the known associated challenges of cement bond, casing thickness, internal surface condition, and the casing outer diameter. Many difficulties are involved when evaluating wells with fiberglass casing. Ultrasonic thickness measurement is practical in a wide variety of materials including metals, plastics, and glass. Materials that are difficult include some cast materials, concrete, wood, fiberglass, and some rubber. Couplants. All ultrasonic applications require some medium to couple the sound from the transducer to the test piece.

macbook black screen soft test

We’ll show you how to set up your 38DL PLUS™ thickness gauge with an M2008 transducer to measure thick fiberglass composites. Learn more at Olympus-IMS.com.S.In many cases, the same gauge that is used for gelcoat measurement can also be used to measure total wall thickness (gelcoat plus fiberglass) using a second transducer, usually an M1036 (2.25 MHz, 0.5 in. element diameter, high sensitivity). The maximum measurable fiberglass thickness is typically about 12.5 mm (0.5 in.). I work in my final project. I willing to design thickness measuring device by using ultrasonic distance sensor. The purpose is measure the thickness fiberglass fishing boat's hull. The thickness hull can be measured by using ultrasonic transducer. The device already available in market. But, My ideas is measuring the fishing boat hull thickness by using .Introduction to Ultrasonic Thickness Gauges For more than fifty years, ultrasonic thickness gauges have been used by quality control professionals to measure the thickness of a wide variety of products across a range of industries. This includes inspectors testing critical parts like aircraft turbine blades for wear and maintenance crews checking pipes and tanks for in-service .

Materials Guide to Ultrasonic Testing Applications in thickness gauges can be used for various fiberglass applications by measuring parts from one side. Fiberglass storage tanks and pipes, for example, can be checked as part of the manufacturing process and while in service to help ensure that no erosion or delamination from corrosive chemicals .Storage of 250,000 readings in up to 1,000 batches and sub-batches; Live graphing of measurement data; Prompted Batch Mode—create pre-defined batches with on-screen text and image prompts for each reading; . UT (Ultrasonic Testing) gauging is an NDT Technique used for measuring the thickness of material (plate, pipe, forging or casting or any other material shape) using the contact pulse-echo technique at temperatures not .

Equipment Used for Fiberglass Thickness Measurements of Boat Hulls The 39DL PLUS™ and 45MG thickness gauges with the High Penetration software option are capable of making digital thickness measurements on fiberglass. .

An ultrasonic thickness gauge can measure most engineering materials, including plastics, metals, metal composites, rubber, and internally corroded materials. Evident is also a leading manufacturer of Hall-effect thickness gauges, which are ideal if you’re looking to achieve fast, precise, and accurate measurements on nonferrous or thin . In this video, we’ll show you how to measure the thickness of a gelcoat layer on top of fiberglass. We’ll go through step-by-step directions on how to set up. An ultrasonic thickness gauge is a non-destructive testing device that measures the thickness of materials using high-frequency sound waves. It helps assess material integrity without causing damage. How does ultrasonic thickness measurement work? Ultrasonic thickness measurement sends sound waves through a material. An ultrasonic thickness gauge is a device used to measure a material’s thickness or the distance between two surfaces. It is widely used in various industries, including manufacturing, maintenance, and quality control, to accurately determine the thickness of metal, plastic, glass, ceramics, and other materials.

Ultrasonic thickness gauges are highly versatile too, as they can be used to measure all common engineering materials, from metals and plastics to composites, fiberglass, and even rub. Lastly, ultrasonic thickness gauges come with onboard storage and data transfer ports (USB or RS232) to transfer measurements to a PC for further analysis.1.1 This practice2 provides guidelines for measuring the thickness of materials using the contact pulse-echo method at temperatures not to exceed 93 °C [200 °F]. . 5.2 Ultrasonic thickness measurements are used extensively on basic shapes and products of .

This measuring effectiveness stems from the ability of the ultrasonic thickness gauge to measure the thickness with access to just one side of the test sample. One other thing is that corrosion gauges use dual element transducers to achieve thickness measurements. . Precision Gauges – For other materials like fiberglass, rubber, ceramic .Thickness measuring is essential across many industries to monitor corrosion, erosion and damage. Ultrasonic thickness measurement (UTM) is commonly used and the method can be applied to a wide range of structures and components that includes ship hulls, piping, pressure vessels and structural steel.

It can be calculated using the formula: Attenuation (dB) = 20 * log10 (Initial Amplitude / Final Amplitude) Thickness Measurement: UT is commonly used for measuring the thickness of materials. The formula for thickness measurement is: Thickness = (Velocity * .

The concept behind the technology is measuring the travel time of acoustic waves in a medium, and correlating them to the elastic properties and density of the material. . Several researchers and engineers have studied the use of ultrasonic testing of concrete in different engineering projects: 1- Pulse Velocity Determination 2- Concrete .

ultrasonic thickness testing

magic mary addix soft test

making fudge soft ball test

Nutty Ladyboy Tube Search (189 videos) Brunettes. 07:00 Ladyboy Nutty In Luxury And Long Legged Pov gettranny, ladyboy, pov, legs, shemale, anal sex, brunettes, lingerie, .

measuring thickness of fiberglass using ultrasonic|ultrasonic gauge diagram